Modern wood floor truss systems have revolutionized construction, providing strong, precise support for floors with longer spans and flexible designs. Prefabricated, crafted to exact standards, they reduce labor, waste, and time. Suitable for various projects, from homes to commercial buildings, they offer durability, energy efficiency, and design freedom. Understanding their benefits helps builders and owners improve structural integrity and project performance.

Wood floor trusses are reshaping how architects and builders approach structural support in homes and commercial spaces. With the increasing need for open, adaptable design, the demand for solutions that allow wider spans and greater layout flexibility continues growing. For those searching for solutions tailored to the West Coast, wood floor trusses California providers deliver expertly engineered systems for various applications.

These modern truss systems are designed not only for robust structural performance but also for efficiencies that save time and money throughout the construction process. As technology and materials advance, these systems enable architects and contractors to achieve more ambitious designs without compromising safety or environmental goals.

Advantages of Using Wood Floor Trusses

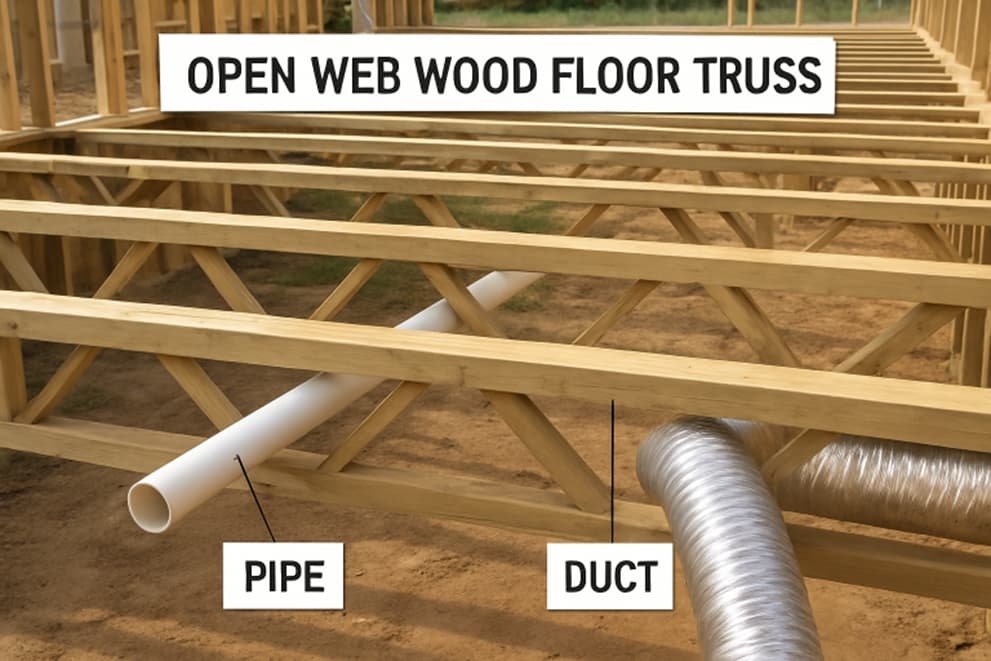

Wood floor truss systems offer significant advantages, leading to their growing adoption in construction projects. These systems can span larger distances than traditional joists, often eliminating the need for support structures. This results in fewer load-bearing walls, allowing for flexible floor plans and better sightlines. A key benefit is their efficient integration of mechanical systems; their open web design provides space for electrical wiring, HVAC ductwork, and plumbing. This preserves structural integrity by reducing penetrations and speeds up installation. Additionally, wood floor trusses are environmentally friendly, made from sustainable materials with a lower carbon footprint compared to concrete or steel. Many are sourced from sustainably managed forests, further reducing ecological impact.

Applications in Residential Construction

Wood floor trusses are revolutionizing residential architecture by supporting the kind of spacious, open-concept layouts that are highly sought after in today’s homes. Whether designing airy great rooms or basement spaces free of obstructive posts, these trusses make it possible to achieve expansive, column-free spans.

The benefit extends to streamlined mechanical work: builders can run HVAC ducts, pipes, and cables directly through the open truss webs, reducing installation time and minimizing headaches for future remodeling projects. Homebuilders also appreciate how the reduced framing requirements can help lower both material and labor costs, making advanced building techniques accessible to a broader range of projects.

Applications in Commercial Construction

Commercial projects – retail stores, office parks, warehouses, and educational institutions – require adaptable structural systems to meet diverse and evolving needs. Wood floor trusses deliver the strength and versatility necessary for these larger-scale undertakings. Their robust load-bearing capacities and long clear spans facilitate wide-open spaces, essential in gymnasiums, event venues, and commercial storage facilities.

Additionally, because these trusses simplify mechanical system routing and can be prefabricated to precise specifications, they help expedite construction schedules. Their flexibility also positions businesses to adapt interior layouts in the future, an increasingly valuable advantage for commercial property owners. To learn more about the wide range of possibilities for contemporary structural systems.

Innovations in Wood Floor Truss Design

Recent advances in open web floor trusses include use of advanced modeling software for optimization, resulting in lighter, durable systems that meet code and green standards. Many incorporate treated lumber to boost resistance to moisture, pests, and fire, extending building lifespan and enhancing long-term performance.

Case Study: Large-Scale Wood Truss Implementation

One standout example comes from a project near Vauxhall, Alberta, where a large farm shop originally slated for steel construction instead used 120-foot-long clear span wood trusses. This resulted in lower costs without sacrificing performance or design ambitions. Such examples underscore the potential of wood truss systems to provide flexible, cost-effective solutions for both modest and monumental spaces. For more details on this project, see recent industry coverage.

Considerations for Implementing Wood Floor Trusses

Project planners should work closely with experienced engineers and truss designers to achieve the best results with wood floor trusses. Critical factors include anticipated load requirements, precise span lengths, compliance with code specifications, and seamless integration with other building systems. Early collaboration in the project lifecycle increases efficiency and reduces the likelihood of costly rework or delays.

Conclusion

Adopting wood floor trusses in modern construction is a testament to their adaptability, sustainability, and efficiency. Their capacity for long, unobstructed spans, the ease of integrating mechanical systems, and their environmental benefits make them a leading choice in today’s residential and commercial projects. As the building industry continues to prioritize both innovation and sustainability, solutions are set to play an increasingly pivotal role in shaping the future skylines of our cities and neighborhoods.

Also Read-Top Memorial Quotes for Celebrating Life and Legacy