The pipe supply industry is undergoing a significant transformation, driven by the dual needs of supporting accelerating urbanization and meeting ambitious environmental objectives. As cities expand and infrastructure ages, pipe suppliers and utility partners face complex pressures to provide reliable, adaptable solutions without compromising the planet. At the forefront of this shift are companies such as Cruco Mill & Industrial Supply North Carolina, which are setting new benchmarks with sustainable products and practices. With resource constraints and regulatory scrutiny rising, these leaders are not only responding to immediate market needs but also making strategic investments to guarantee long-term viability.

Across the supply chain, industry players are evaluating everything from raw material sourcing to deployment and decommissioning processes, placing a growing emphasis on how products impact both the bottom line and the world at large. This mirrors a broader evolution toward sustainable infrastructure seen in related sectors, where eco-innovation is crucial for future readiness, climate resilience, and industry reputation. The modern pipe supply industry, therefore, represents not only a response to operational challenges but also an opportunity to realize broader societal and environmental benefits.

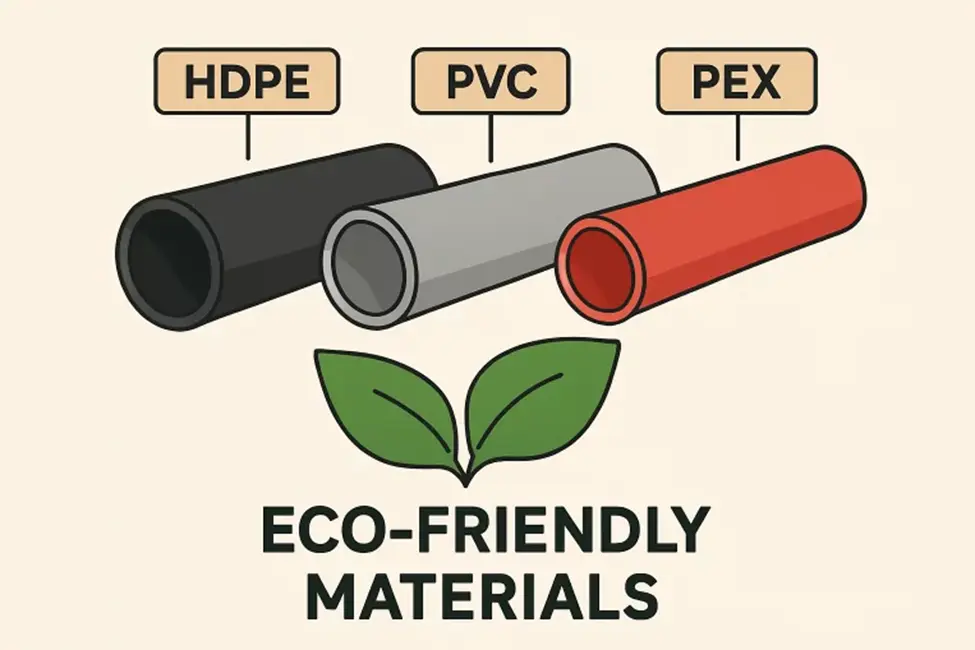

Embracing Eco-Friendly Materials

The adoption of eco-friendly materials marks a major turning point in the global pipe supply market, reflecting a broader commitment to green principles. Historically, cast iron and steel pipes dominated the industry, but these traditional materials are increasingly being replaced by high-density polyethylene (HDPE), polyvinyl chloride (PVC), and cross-linked polyethylene (PEX). Unlike their predecessors, these modern alternatives require significantly less energy during production and are lighter, which greatly reduces costs and carbon emissions associated with transportation. Not only does this decrease environmental impact, but the improved corrosion resistance and greater flexibility of these pipes also extend their operational lifespan. This means fewer frequent replacements, which translates to substantial savings in both resources and labor over decades.

As businesses and municipalities turn their attention to reducing lifecycle costs, demand for sustainable pipe materials continues to soar. Besides environmental advantages, these materials also prove cost-effective in the long run, bolstering ROI on infrastructure investments. They are also more compatible with new installation technologies and support broader climate adaptation goals, allowing communities to future-proof their water, gas, and sewage networks. Eco-friendly materials, therefore, have become the gold standard for modern infrastructure project specifications.

Integration of Smart Technologies

Technology-driven innovation is rapidly revolutionizing how water and utility infrastructure is planned, implemented, and maintained. The integration of smart sensors, meters, and advanced data analytics enables real-time monitoring and actionable insights across pipe networks. These devices detect everything from changes in water pressure to the presence of contaminants, providing an early warning system for leaks or system failures. With continuous streams of data, utility operators can quickly identify and resolve problems, reducing downtime and preventing wasteful water loss—issues that have historically resulted in enormous financial and resource costs.

In addition, this smart infrastructure supports the broader vision for smart cities, where integrated digital systems improve resource efficiency and enhance public safety. Today, the proliferation of smart technologies is expanding beyond pilot projects to large-scale, municipality-wide deployments. These upgrades not only transform operations but also help conserve vital resources, lower maintenance expenditure, and even limit greenhouse gas emissions by optimizing energy use. As investment in digital utilities grows, advanced pipe supply systems are fast becoming a critical backbone of tomorrow’s resilient and intelligent cities.

Advancements in Manufacturing Processes

Dramatic advances in manufacturing lie at the heart of the industry’s sustainable transformation. Factories today are equipped with cutting-edge machinery, such as computer-driven extruders, that ensure incredible precision and consistency. Automated quality control systems now detect and rectify defects instantaneously, which not only improves the reliability of finished products but also reduces material waste. Modern processes—including the use of recycled heat and energy-efficient drive systems—have sharply lowered the carbon footprint associated with pipe fabrication.

This push for smarter, cleaner manufacturing delivers savings and flexibility to distributors and contractors, who can now access more custom solutions in shorter timeframes. The newfound agility is crucial, especially as projects scale or shift scope to address evolving regulatory, climate, or customer-driven requirements. By integrating advanced technologies in manufacturing, the industry is not just meeting current market needs but establishing itself as a leader in responsible industrial production, setting standards for quality, efficiency, and stewardship.

Focus on Recycling and Circular Economy

Sustainability in the pipe supply sector is further accelerated by a focus on the circular economy—a model that advocates minimizing waste and maximizing material reuse. Industry innovators now produce pipes containing substantial amounts of post-consumer recycled content, particularly in the polyethylene (PE) and PVC categories. Thanks to breakthroughs in materials science, these high-content recycled pipes demonstrate durability, performance, and safety on par with those made entirely from virgin materials. Some pipes now consist of up to 50% recycled material, driving down their carbon footprint throughout the product’s lifecycle.

The adoption of circular economy principles doesn’t end at manufacturing. Pipe supply companies also offer take-back schemes and recycling initiatives for old or surplus pipes, ensuring that end-of-life products are repurposed rather than contributing to landfill. This creates a closed-loop system that supports municipal sustainability targets and strengthens industry credibility. As environmental regulations tighten and consumer demand for green products grows, businesses that embrace recycling and circularity are likely to shape sustainable urban development.

Adoption of Trenchless Technology

Trenchless construction techniques are rapidly redefining how pipelines are installed in urban environments. Instead of large-scale excavation, methods such as pipe bursting, slip lining, and cured-in-place pipe (CIPP) allow contractors to repair or lay new pipes with minimal surface disruption. This groundbreaking approach preserves existing roads, landscaping, and utilities, dramatically reducing project timelines and public inconvenience. It also plays a substantial role in sustainability by lowering emissions and noise, decreasing fuel use, and protecting mature urban ecosystems.

Trenchless technology is especially valuable in densely populated cities, where access is limited and infrastructure is aging. The ability to upgrade essential networks with minimal interruption supports not only operational efficiency but also economic continuity for businesses and communities. As this construction practice gains traction, it’s being recognized as a sustainable alternative that aligns with climate resilience goals while meeting the infrastructural needs of modern metropolitan areas.

Regulatory Compliance and Quality Assurance

An uncompromising commitment to compliance and quality assurance is essential in an era of heightened regulatory scrutiny. Pipe manufacturers and suppliers adhere to rigorous international standards, such as ISO 4422 for potable water transport or ASTM D1785 for pressurized systems, to ensure every product exceeds safety and performance benchmarks. This is not just about meeting legal requirements—it’s about instilling confidence and protecting public welfare. State-of-the-art laboratories frequently test products for pressure resistance, chemical stability, and impact strength, offering further assurance to customers and end-users.

Beyond technical excellence, these certifications open new markets and offer peace of mind for stakeholders managing critical infrastructure. As the global trade in industrial goods expands, high standards function as a universal language, facilitating business relationships and adopting best practices worldwide. Compliance, therefore, is both a shield and a selling point in the pipe supply sector, anchoring industry reputation on a foundation of trust and reliability.

Conclusion

Today’s pipe supply sector is no longer defined solely by durability and price. Instead, the industry has fundamentally repositioned itself, putting the goals of sustainability and technology-driven progress at the forefront of its business model. Through the adoption of greener materials, smart solutions, advanced manufacturing, circular economy principles, trenchless technology, and uncompromising quality controls, pipe suppliers are building the infrastructure of tomorrow. Pioneering companies are prime examples of how leadership and innovation are creating resilient, eco-conscious urban environments prepared to meet the future challenges.

Also Read-Data Science Innovations Transforming the Fintech Landscape