Choosing the right manufacturer for a Laser cutting machine can significantly impact your overall experience, encompassing performance, reliability, support, and long-term value. With numerous options available, it’s essential to know what to look for before investing. Whether you’re purchasing for a growing business or expanding your current setup, this guide will walk you through key factors that can help you identify the best manufacturers. From build quality and technology to customer reviews and after-sales service, every detail matters when selecting the right partner in your laser cutting journey.

Here’s How To Look For The Best Manufacturers Of A Laser Cutting Machine

Check the manufacturer’s industry reputation

To find the best manufacturers of laser cutting machines, start by checking the manufacturer’s industry reputation. A well-regarded manufacturer often has a consistent track record of delivering high-quality machines and reliable service.

Look into how long they’ve been in business, the type of clients they’ve worked with, and any industry awards or recognitions they’ve earned. Reputable manufacturers are usually known for their commitment to quality, innovation, and customer satisfaction—factors that can give you confidence in your purchase decision.

Review product specifications and build quality

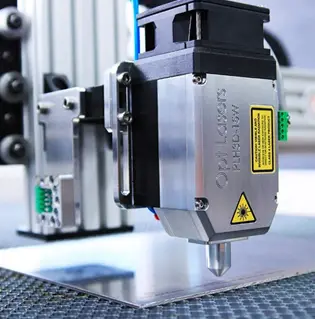

To look for the best manufacturers of a laser cutting machine, it’s essential to review product specifications and build quality. Carefully examine the materials used in the machine’s construction, the precision of its components, and the durability of its design.

Pay attention to key specifications such as cutting speed, power output, support materials, and software compatibility, as these factors directly impact performance. A manufacturer that provides transparent, detailed specs and demonstrates strong engineering standards is more likely to deliver a machine that meets your operational needs and lasts over time.

Compare technology and innovation features

To find the best manufacturers of a laser cutting machine, it’s essential to compare their technology and innovation features. Leading manufacturers often stand out by integrating advanced capabilities such as automation, smart controls, cloud connectivity, or enhanced precision systems.

By comparing the tech advancements each brand offers, you can determine which machines are designed for efficiency, accuracy, and future-ready performance. Manufacturers that consistently invest in innovation typically demonstrate a strong commitment to meeting evolving industry demands and staying ahead of their competitors.

Evaluate customer support and after-sales service

To find the best manufacturers of laser cutting machines, evaluate the quality of their customer support and after-sales service. Reliable manufacturers understand that purchasing the machine is just the beginning, and they back their products with responsive assistance, clear communication, and accessible maintenance solutions.

Verify whether they provide training, troubleshooting assistance, and expedited access to spare parts. Strong after-sales service not only reduces downtime but also reflects the manufacturer’s commitment to long-term customer satisfaction. A company that stands by its product is more likely to be a trustworthy partner for your operations.

Read verified client testimonials and case studies

To find the best manufacturers of laser cutting machines, take the time to read verified client testimonials and case studies. These firsthand accounts offer valuable insights into how the machines perform in real-world settings and how the manufacturer handles customer relationships. Look for patterns in feedback, such as consistent praise for reliability, service, or ease of use, as well as any recurring concerns.

Case studies can also highlight how different industries have successfully implemented these machines, providing a clearer picture of their versatility and effectiveness. Reliable manufacturers are usually transparent in sharing these experiences to build trust and credibility.

Assess customization options and scalability

To find the best manufacturers of laser cutting machines, assess the customization options and scalability they offer. A good manufacturer understands that every business has unique needs and should provide machines that can be tailored to specific applications, material types, or production volumes.

Whether it’s adjustable power settings, modular upgrades, or software integrations, the ability to customize ensures the machine fits seamlessly into your workflow. Additionally, consider whether the manufacturer supports future scalability, allowing you to expand or upgrade your setup as your business grows. This flexibility is a strong indicator of a forward-thinking and customer-focused manufacturer.

Verify certifications and compliance standards

To find the best manufacturers of laser cutting machines, verify their certifications and compliance with industry standards. Reputable manufacturers typically adhere to recognized quality and safety benchmarks, such as ISO certifications or CE markings, which indicate consistent production practices and equipment reliability.

These certifications also ensure that the machines meet regional and international regulations, making them suitable for use in professional settings. Confirming these details helps you avoid unverified products and ensures you’re investing in machinery that’s built to recognize standards of performance and safety.

Why To Look For The Best Manufacturers Of A Laser Cutting Machine

Finding the best manufacturers of a laser cutting machine is a crucial step to ensure long-term value, reliability, and optimal performance.

A well-established manufacturer not only delivers high-quality machines but also provides dependable support, clear documentation, and technology that is future-ready.

Choosing the right manufacturer reduces the risk of breakdowns, inefficiencies, or unexpected costs down the line.

It also gives you confidence that the equipment is built with precision, complies with industry standards, and can adapt to your evolving needs.

In a competitive market, partnering with a trusted manufacturer sets a strong foundation for smooth operations and business growth.

Things To Check Before Buying A Laser Cutting Machine

Before purchasing a laser cutting machine, several key factors should be considered to ensure a sound investment.

Start by reviewing the machine’s technical specifications, such as power output, cutting speed, supported materials, and bed size, to ensure they match your project requirements.

Examine the build quality and durability of components to gauge how well the machine will perform over time.

It’s also important to assess the software compatibility and user interface for ease of operation.

Don’t overlook the manufacturer’s reputation, customer support, and warranty terms, as these factors play a major role in long-term satisfaction and efficiency.

Wrapping Up

Finding a trusted laser cutting machine manufacturer is all about knowing what to look for and asking the right questions. From checking the company’s industry reputation and evaluating product quality to reviewing client feedback and ensuring solid after-sales support, each step plays a vital role in your decision-making process. A reliable manufacturer doesn’t just sell a machine—they offer long-term value, technical confidence, and a partnership you can count on.

Also Read- Boost Your Business Visibility with Mobile Advertising