Introduction

Heat press printing has rapidly gained popularity in the custom apparel world due to its flexibility, efficiency, and ability to deliver professional results. One of the driving innovations in the field is the use of white toner printers, which empower creators to produce vibrant, full-color transfers—even on dark fabrics—by combining advanced printing technology with heat pressing techniques. Whether for hobbyists creating one-off designs or entrepreneurs scaling up apparel businesses, understanding the essentials of heat press printing can make all the difference in quality and creativity.

The simplicity and speed of heat press printing set it apart from other methods. Unlike traditional screen printing, which requires messy inks and complex setups, heat press printing relies on controlled application of heat and pressure, resulting in clean, consistent outcomes. Choosing the right tools and methods, such as leveraging white toner printers for specific designs, allows users to print detailed artwork and full photographs onto garments with a little learning curve.

Understanding Heat Press Printing

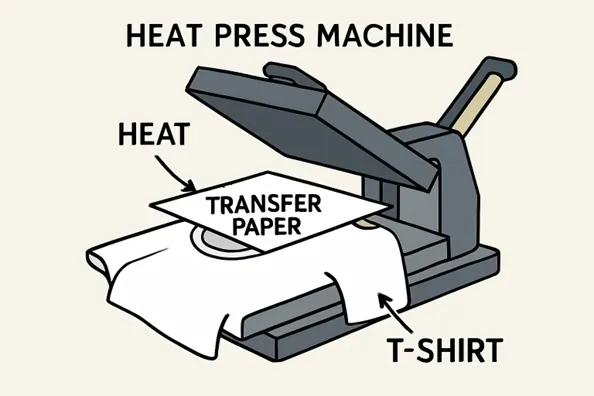

Heat press printing combines heat and pressure to transfer designs from specialized transfer paper or vinyl onto fabric. The core advantage is its remarkable ability to produce sharp, lasting prints regardless of project scale. In practice, you start by preparing your design digitally, then print onto a transfer medium. This medium is then placed on the t-shirt and subjected to precise heat and pressure for a specified duration, bonding the design to the garment.

Choosing the Right Heat Press Machine

The right machine is essential for repeatable, high-quality output. The three main types each serve unique needs:

- Clamshell Heat Press: The top plate opens on a hinge, making it ideal for small workspaces and straightforward operations. Due to its compactness and user-friendliness, it’s recommended for beginners.

- Swing-Away Heat Press: The top plate swings completely away from the base, providing full access for precise garment placement and reducing the likelihood of accidental burns. This is a superior option for detailed designs and thicker materials.

- Draw Heat Press: This model’s lower platen slides out, allowing you to lay out garments safely and precisely and minimizing heat exposure during setup.

Essential features to prioritize include digital temperature and time controls, adjustable pressure, and interchangeable platens for maximized versatility across projects.

Selecting Appropriate Materials

The fabric and transfer materials you choose are crucial for end product quality. Commonly used options are:

- Heat Transfer Vinyl (HTV): HTV is ideal for bold, single- or multi-color designs. It is cut to shape, placed on the garment, and sealed with heat and pressure. The result is a long-lasting, flexible imprint in various textures and effects.

- Sublimation Transfers: Best for high-polyester content fabrics, sublimation embeds dye directly into the fibers, producing exceptionally vivid images. This is perfect for performance wear or objects that require high durability and colorfastness.

- Transfer Paper: Compatible with inkjet or laser printers, this paper produces full-color, photo-quality results and works on both light and dark garments (the latter requiring specific dark transfer papers).

When selecting materials, always consider the type of garment, its color, and the image complexity, as each element affects the overall look and longevity.

Step-by-Step Guide to Heat Pressing

- Design Preparation: Create or choose a high-resolution image, remembering to mirror the design if using words or directional graphics so they appear correctly after transfer.

- Printing the Design: Print it onto the correct transfer medium, ensuring the printer and paper combination suits the chosen fabric and design requirements.

- Prepping the T-Shirt: Place the shirt flat on the press platen. A brief pre-press will remove all wrinkles and moisture, helping prevent defects during the main transfer.

- Positioning the Design: Apply the transfer to the desired print area. Use heat-resistant tape for precision with intricate layouts.

- Applying Heat and Pressure: Lower the heat press and use time, temperature, and pressure settings specified by your transfer material manufacturer to ensure proper bonding.

- Peeling the Transfer: After pressing, remove the backing paper per recommended instructions—hot, warm, or cold peel—according to material guidelines for the best finish.

Common Mistakes and How to Avoid Them

- Incorrect Temperature or Pressure: Manufacturers provide ideal settings for a reason; deviating can result in peeling, fading, or damage. Double-check instructions for every new material used.

- Skipping Pre-Pressing: Moisture trapped in fabric can cause bubbling or failed adhesion. Always prepare garments by pre-pressing before applying transfers.

- Improper Alignment: Uneven or off-center prints are a common oversight—use rulers, templates, or laser guides for accuracy every time.

Caring for Heat-Pressed T-Shirts

Proper care extends the vibrancy and lifespan of custom t-shirts:

- Wash inside out in cold water with mild detergents to preserve the design.

- Avoid bleach or fabric softeners, which deteriorate print quality.

- Hang drying is preferred; tumble dry on low heat if using a dryer.

- Don’t iron directly over the printed area. Instead, flip the shirt inside out or use a pressing cloth on the design.

Read more practical tips on garment care from the New York Times Wirecutter laundry guide.

Advantages of Heat Press Printing

- Cost-Effective: It is ideal for low-volume runs since a costly setup is not required, making it accessible for side businesses and one-off projects.

- Versatility: It works with cotton, polyester, blends, and other fabrics; users can print on flat surfaces, including textiles, bags, and even mousepads.

- High-Quality Results: Intricate details and photo-realistic prints are achievable, especially using advanced equipment and media.

- Quick Turnaround: The fast process makes it well-suited for on-demand jobs or time-sensitive orders.

This comprehensive Printing News article explores more heat press techniques and industry advancements.

Conclusion

With thoughtful selection of machines, materials, and best practices, heat press printing can help anyone—from enthusiastic DIYers to ambitious business owners—produce standout custom t-shirts. Embrace new technologies and techniques to push your creativity further, and always follow care instructions to keep your custom creations looking their best. Mastery of heat press printing ensures durability and visual appeal and keeps your production nimble and competitive in a growing custom apparel marketplace.

Read more: The Best Family Cars for Safety, Comfort, and Value – Croudmomentum.com

From Year One to Year Thirty: Symbolism in Service Anniversary Awards

Benefits of Family Board Game Nights – Croudmomentum.com